X-ray System for Boilers and Pipes

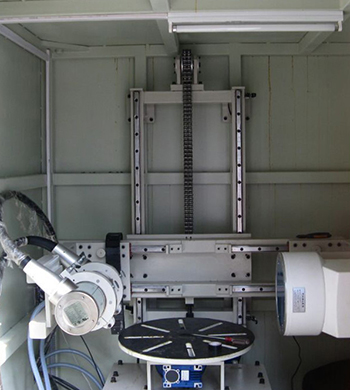

X-ray Inspection System for Boilers and Pipes consists of Utility frequency X-ray Generator, Image Intensifier, Mechanical Transmission System, Computer Image Processing System, Control Device and Lead NDT room. The system can quickly and accurately detect the circumference weld defects in boiler pipes, observed through the imaging display. With high degree of automation, rapid detection speed, the system greatly improve the efficiency of NDT tasks, and at the same time reduces the cost of inspection. The system is robust and easy to operate, has simple user interface, customizable software functions according to the detection requirements.

X-ray Inspection System for Boilers and Pipes consists of Utility frequency X-ray Generator, Image Intensifier, Mechanical Transmission System, Computer Image Processing System, Control Device and Lead NDT room. The system can quickly and accurately detect the circumference weld defects in boiler pipes, observed through the imaging display. With high degree of automation, rapid detection speed, the system greatly improve the efficiency of NDT tasks, and at the same time reduces the cost of inspection. The system is robust and easy to operate, has simple user interface, customizable software functions according to the detection requirements.

Technical Specifications:

| Item | Origin | Model | Type |

| X-ray Tube | US Switzerland | 10-450kV | Metal Ceramic |

| High Voltage Generator | Imported China | Utility Frequency/ High Frequency/ Constant Frequency | 225KV |

| Control Console | China | DTK-1 | For Imported China Generator |

| Imported | US Switzerland | For Imported Generator | |

| Cooling System | China | Oil Cooling | 3010-4510 KV |

| Water Cooling | Less than 225KV | ||

| Generator Wheel Kits | China | U-Type | Hoisting |

| C-Type | Fixed | ||

| Customized | According to the actual situations | ||

| Imaging Device | China | Real-Time Imaging | 2D Graphics |

| China Imported | Flat Panel Imaging | 2/3D Graphics | |

| Mechanical Transmission System | China | 2D | Basic |

| 3D | Standard | ||

| 5D | Multi-Function | ||

| Protection System | China | Protection Room | Construction |

| Lead Room | Made of Lead | ||

| High Voltage Cable | Imported | 5-20M | HV Resistant |

| Image Processing System | China | DTK-2 | Human - computer Interaction |

| Detection Material | Steel, Copper Copper Alloy, Aluminium Aluminium Alloy, Titanium Titanium Alloy, Nickel/Nickel Alloy | ||

| Standard Penetration Thickness (mm) | Q235:2-250 | ||